![]()

Track and Trace System Technology

Processcolor has developed Track & trace, a concept which unites product tracking and proof of authenticity. The core component is a physically secured code. Each product is assigned an individual code and is equipped with a counterfeit-proof identification label such as the tesa Holospot®. This label stores information over several levels, which can be read, in turn, with the naked eye, with a magnifying glass, or exclusively by a reading device. This means security is applied directly onto the product or packaging, enabling its authenticity to be instantly verified and the product itself to be efficiently traced.

The Track and tracee concept can be easily integrated into existing logistics processes. Goods tracking systems based on barcodes, 2D matrix codes or RFID and NFC technology are simply integrated into brand protection. It is thus possible, for instance, to register products on an individual basis during production and associate them with a transport packing code when they are packed and later link the packaging with an RFID pallet label. Orders can be assigned to individual pallets and traced by incorporating additional IT systems, such as SAP or customs and excise databases. In this way, tesa® trust & trace provides reliable data for quality control and recall campaigns in logistics systems. The advantages for brand protection are also self-evident. All parties in the logistics process as well as customs and excise officers, distribution partners and end consumers can establish a product’s authenticity at any time.

The Trace and Track achived through

Web Based Tracking:- By inputting Serial Number of the product or case user can track all the information about the product instantly using website. Using Web Based information system, “Product Information can be tracked on line by passing Product Serial Code”.

SMS Based Tracking:- By sending Serial Number of the product to a given mobile number user can instantly get the information about the product or case via SMS. Using SMS Based tracking system. “By sending SMS to Pre-Defined local number user can get the information about the products

MMS Based Tracking:- By sending snapshot of the product’s 2D Barcode without need of typing serial number using MMS protocol user can get the required information on his mobile phone. A unique feature in the MMS Based system is that “By taking snap of the Barcode image and transforming same to MMS gateway user can get product’s information without typing serial number.

Mobile Application Based Tracking:- Inspection Officer can track the required product or case information using mobile phone instantly from the server. Using Mobile Application Based system “Pre-Configured menu based mobile application will be deployed for inspection staff to track the product and cases information”.

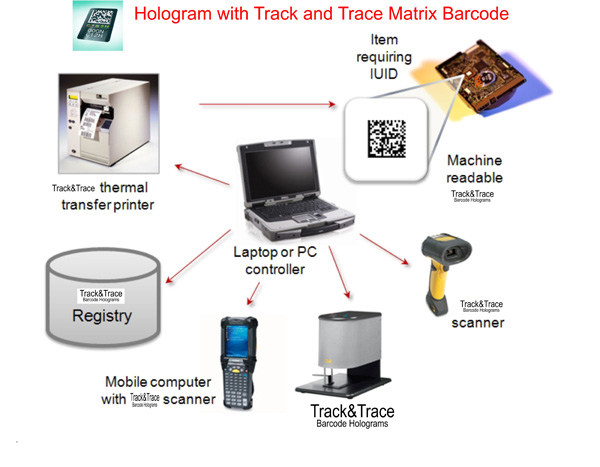

Track & Trace Architecture:-